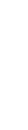

When designers and engineers analyze the physical performance of metals and advanced composites based on their weight contributing basis, there is a quantifiable gap between the high performance, high price and design limitations inherent to hot-melt advanced composite pre-pregs and the much more affordable, but heavier metals.

IDI’s materials engineers have developed methods to move our standard line of thermoset compounds into a higher echelon of materials called Structural Thermoset Composites, “bridging the gap” between specific stiffness and specific strength, while offering a product at a lower price than an advanced composite.

Download the Fortium / Ultrium Brochure (pdf) here.

Structural Thermoset Composites are engineered composites that represent a new product technology from IDI that addresses the needs of specific high-performance applications requiring exceptional strength and rigidity, plus resistance to extreme temperatures and corrosive environments. Structural thermosets consist of high glass fiber or carbon fiber reinforcement in a polymer resin. The fiber provides strength and stiffness, while the resin protects the fibers and gives the material its shape. The properties of a high-performance compound can be changed by varying the type and quantity of its ingredients. Fiber type, length, and mix proportion help determine properties such as strength and rigidity. Resin characteristics can be changed to provide the desired heat and corrosion resistance.

The most common thermoset resins are polyester, vinyl ester, polyurethane, and epoxy. Each of these resins has its own price and performance characteristics, so selection is based on the functional and cost requirements of the application. For instance, design engineers might choose vinyl ester resin for corrosion-resistant products, epoxy resin for high-strength applications, or polyester resin when good overall performance and cost are the driving factors.

As for reinforcement, many types of fiberglass materials can be used in structural thermosets, depending on the molding process and the product’s strength requirements. Glass reinforcement options include chopped strand, mat with random fiber orientation, light textile fabrics, heavy woven materials, knitted materials, and uni-directional fabrics. Fiber lengths range from 1/2-2.0 inches (12.7mm – 50.8mm) for SMC and 1/32-1/2 inch (.75-12.7mm) for BMC. IDI also offers carbon fiber reinforcement for applications that require exceptional strength coupled with severe weight restrictions.

Innovative companies are switching to IDI’s Structural Thermoset Composites (STC®) to replace heavier, more expensive and less flexible materials like metals and advanced composites. Structural thermosets are high performance composites that are distinguished from standard SMC and BMC by the use of more specialized resins combined with higher levels of reinforcement (glass, carbon, aramid, etc.). The resulting fiber reinforced composite material satisfies unique performance requirements. Structural thermosets improve the design, manufacture, and durability of a broad range of products, causing many design engineers and molders to convert their product designs to Structural Thermoset Fortium® and Ultrium®. Consisting of fiber-reinforced polymers with cross-linked molecules, these products offer a number of advantages over metals and thermoplastics, including higher strength per unit weight, better dimensional stability and corrosion resistance, greater design flexibility, and lower overall costs.