Case Study

End Of Train Units

inquiry

End of train units are an important safety feature of the rail industry. These units are used in telemetry to communicate important data about one part of a train to another. In this case, information about the brake line pressure and other critical information is communicated from the end of the train to the front. Because these units are mounted on the end of trains and constantly exposed to the elements, they must be resistant to extreme cold and vibration. In addition, because in some instances the units are carried by hand from one end of a train to the other, they must also be lightweight.

idea

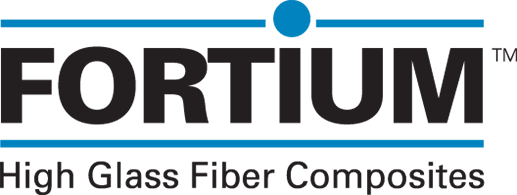

Traditionally, this unit has been made of Aluminum, but when developing the new 2020-He ETD, DPS Electronics wanted something that would give them an even lighter unit but still match or exceed the durability of their old unit. They found both in IDI Composites' Fortium™ STC-2158. Fortium™ is a series of composite products reinforced with 40% - 65% discontinuous glass fiber which imparts high strength and impact resistance to these composite materials. Combined with an innate resistance to temperature fluctuations, Fortium™ was the perfect choice to meet all of the critical design needs of the part.

innovation

The 2020-He ETD is the only end of train unit on the market that is made from IDI's STC-2158, and the response from customers has been very positive. The lighter weight unit has made a huge impact with associates who enjoy using it. Furthermore, the DPS 2020-He ETD case has 102 drilled screw holes and 9 routed windows. Fortium™ is ideal for this complex shape – it is easy to drill and fairly flexible, while still providing overall strength and durability.

Fortium™ - High Glass Fiber Composites

Structural Thermoset Composites |

|||||||

|

Product: 2150 (VE-GF50) |

|||||||

Properties |

Test Method |

Value |

|||||

Flexural Strength |

ASTM D-790 |

468.2 MPa |

|||||

Flexural Modulus |

ASTM D-790 |

18.9 GPa |

|||||

Tensile Strength |

ASTM D-638 |

314.9 MPa |

|||||

Tensile Modulus |

ASTM D-638 |

24.1 GPa |

|||||

Notched Izod |

ASTM D-256 |

19.22 J/cm |

|||||

Unnothched Izod |

ASTM D-256 |

28.29 J/cm |

|||||

Density |

ASTM D-792 |

1.62 g/cm3 |

|||||

|

Click to download a pdf of the STC 2150 Data Sheet |

|||||||

The information on this sheet is a guide. The stated values reflect an average of several tests conducted on Composites International’s (CI's) goods. These values were obtained under ideal conditions and may not be replicated in any particular test, part, or application. Because the values achieved in actual parts depend considerably on part design, molding conditions, and testing methods, no guarantee is made or implied regarding values to be obtained in any specific test, part, or application. CI makes no warranty or representation as to the suitability of any of its goods for use in any application. CI relies on customer to conduct its own tests and judge for itself the suitability of CI's goods.