Case Study

inquiry

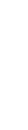

Horton, Inc. is a premium provider of engine cooling solutions worldwide, manufacturing and marketing fan drives, fans and related components in OEM applications and aftermarket segments. Their products are constantly exposed to highly corrosive and high heat environments. Metals were the standard answer for cooling needs, but the corrosive environment in an engine poses a challenge for most metals, and the higher cost of metals translates into a more expensive part. Many of their fans are designed to cool oversized construction equipment and are over 5 feet tall; the use of metals also dramatically increases weight.

idea

Horton worked closely with IDI Composites International and their 3i Composite Technology Center and Ashley Industrial Molding to develop and test parts made from IDI’s new line of Fortium composites. It was determined the Fortium product line met the requirements for Horton to develop a superior fan blade to cool the engines of large vehicles and stationary equipment for mining, construction and the oil and gas industries. The high-strength composite fan blade was designed to overcome limitations that metal fans encounter with equipment operating in difficult environments.

innovation

Horton’s computer-optimized blade designs allow for improved airflow performance and reduced noise, previously not achievable by stamped metal blade designs, and are now possible to mold with a composite material. The material strength-to-weight ratio and durability allow high fan speeds in operating environments with vibration, dust, grime, corrosive elements and temperatures that range from frigid to scorching, and the material allows unmatched durability to reduce maintenance costs. The resulting fan performs more efficiently than current metal fans in the market, improving airflow performance, reducing noise and fuel consumption. The new blade designs are not limited to engine cooling, allowing for expansion into many aspects of airflow management in harsh environments, such as cooling towers or agricultural ventilation.