Fortium™ SMC + QISO® – Better Together

Fortium™ SMC with QISO® – High-Performance, Lightweight Solutions for Complex Geometries

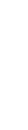

At IDI Composites International, we combine our advanced Fortium™ SMC with A&P Technology's QISO® fabric to create a superior solution for high-stress applications. This chemically matched prepreg enables a reduction in SMC usage while increasing strength and reducing mass, cost, and waste. By strategically layering 0°, +/-60° QISO with Fortium™ SMC, we optimize performance and efficiency in complex molding processes.

Our Fortium™ SMC is a discontinuous fiber-reinforced composite that provides proven resilience against UV radiation and chemicals. QISO® is a 0°, +/-60° fabric that enhances strength, impact resistance, and manufacturability. Its balanced, symmetric architecture simplifies cutting and nesting, further minimizing waste. The co-molding of Fortium™ SMC and QISO® results in parts that are not only stronger but also more sustainable.

The Perfect Combination for High-Stress Applications

Fortium™ SMC and QISO® share the same fiber loading by weight, simplifying design parameters. For areas requiring higher strength, one layer of QISO® can replace one layer of SMC, meeting mechanical requirements without compromising on performance. This seamless integration makes Fortium QISO as easy to cut, lay, and cure as standard SMC, ensuring a streamlined manufacturing process.

Thanks to QISO’s quasi-isotropic architecture, properties remain consistent in every direction, improving nesting and reducing material waste. This allows for the production of lighter, higher-performing parts that can be molded into both simple and complex geometries. For example, in a truck bed manufacturing application, key stress areas were reinforced with Fortium QISO, resulting in a stronger, more resilient product.

Preliminary trials have shown that Fortium QISO molds well in larger-scale tooling, successfully forming rib structures and adapting to intricate shapes with ease.

Unmatched Performance

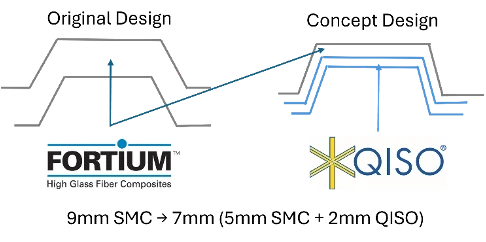

Impact testing comparing a standard SMC panel with a 20% thinner panel reinforced with Fortium QISO has demonstrated significant improvements:

Same Tensile Strength

25% Higher Flexural Strength

Enhanced Impact Resistance

Fortium QISO offers a game-changing solution for producing lightweight, high-performance parts that maintain their strength while reducing thickness and conforming to complex geometries.

For more details on this case study:

Property |

Fortium F250-UV (SMC) |

Fortium QISO |

Glass Fiber |

48-52% |

48-52% |

Specific Gravity |

1.7 – 1.8 |

1.7 – 1.8 |

Sheet Weight |

5.4 kg/m2 |

2 kg/m2 |

Impact Testing shows major improvement using Fortium + QISO